Transmission Line Insulator Flashovers

Contamination caused insulator flashovers produce frequent outages in severely contaminated areas. Lines closer to the ocean are in more danger of becoming contaminated. Several countermeasures have been proposed to improve insulator performance.

The most frequently used methods are:

- Increasing leakage distance

- Semiconducting glaze

- Periodic washing

- Periodic cleaning

- Replacement

- Covering with silicon rubber

- Covering with petroleum

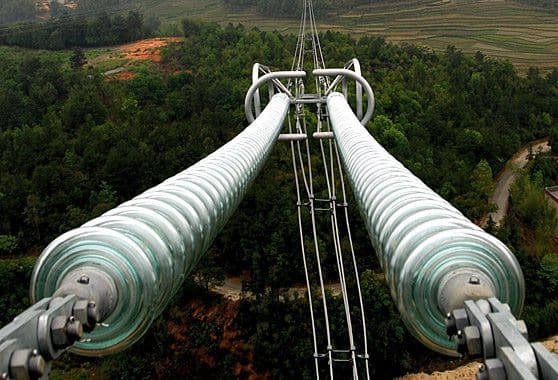

1. Increasing leakage distance

Increasing leakage distance by increasing the number of units or by using fog-type insulators.

The disadvantages of the larger number of insulators are that both the polluted and the impulse flashover voltages increase. The latter jeopardizes the effectiveness of insulation coordination because of the increased strike distance, which increases the overvoltages at substations.

2. Semiconducting glaze

Application insulators are covered with a semiconducting glaze.

A constant leakage current flows through the semiconducting glaze. This current heats the insulator’s surface and reduces the moisture of the pollution. In addition, the resistive glaze provides an alternative path when dry bands are formed. The glaze shunts the dry bands and reduces or eliminates surface arcing. The resistive glaze is exceptionally effective near the ocean.

3. Periodic washing

Periodic washing of the insulators with high-pressure water.

The transmission lines are washed by a large truck carrying water and pumping equipment. Trained personnel wash the insulators by aiming the water spray toward the strings. Substations are equipped with permanent washing systems. High-pressure nozzles are attached to the towers and water is supplied from a central pumping station.

However, major drawbacks of this method include high installation and operational costs.

4. Periodic cleaning

Periodic cleaning of the insulators by high pressure driven abrasive material.

Periodic cleaning by materials such as ground corn cobs or walnut shells. This method provides effective cleaning, but cleaning of the residual from the ground is expensive and environmentally undesirable.

5. Replacement

Replacement of porcelain insulators with non-ceramic insulators

Non-ceramic insulators have better pollution performance, which eliminates short-term pollution problems at most sites. However, insulator aging may affect the long-term performance.

6. Covering with silicon rubber

Covering the insulators with a thin layer of room-temperature vulcanized (RTV) silicon rubber coating.

This coating has a hydrophobic and dirt-repellent surface, with pollution performance similar to non-ceramic insulators. Aging causes erosion damage to the thin layer after 5-10 years of operation. When damage occurs, it requires surface cleaning and a reapplication of the coating.

Cleaning by hand is very labor intensive. The most advanced method is cleaning with high pressure driven abrasive materials like ground corn cobs or walnut shells. The coating is sprayed on the surface using standard painting techniques.

7. Covering with petroleum

Covering the insulators with a thin layer of petroleum or silicon grease.

Grease provides a hydrophobic surface and absorbs the pollution particles. After one or two years of operation, the grease saturates the particles and it must be replaced. This requires cleaning of the insulator and application of the grease, both by hand.

Because of the high cost and short life span of the grease, it is not used anymore.

Reference: The electric power engineering handbook – L.L. Grigsby (Purchase hardcover book from Amazon)